When electrical charging systems fail, sourcing the right alternator becomes critical. Many organizations today choose to buy rebuilt alternator units as a cost-efficient and reliable solution. This guide explains what rebuilt alternators are, how they compare to other options, and what technical and operational factors should be considered before procurement.

Understanding the Role of an Alternator

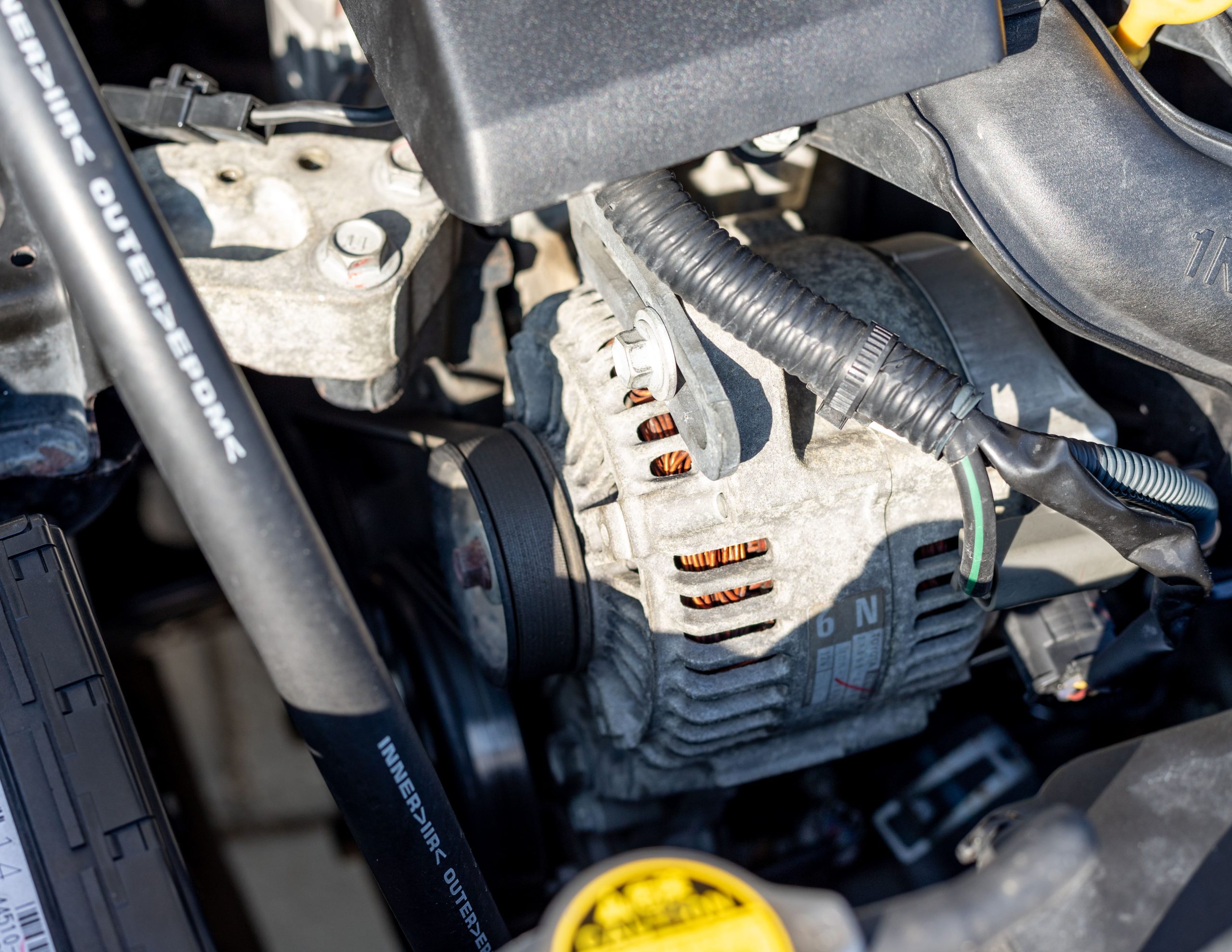

An alternator supplies electrical power and maintains battery charge while the engine is running. Malfunctioning alternators can lead to:

- Inconsistent power supply to vehicle systems

- Frequent battery depletion

- Warning signals on dashboards or diagnostic equipment

- Irregular performance of electrical components

Recognizing these indicators early ensures timely replacement and avoids operational downtime.

Types of Alternators: Key Differences

Procurement teams often evaluate multiple categories:

- New Alternators – Manufactured entirely from new components, offering maximum service life but at higher cost.

- Rebuilt Alternators – Disassembled, inspected, and repaired with defective components replaced. Quality depends on process and testing standards.

- Remanufactured Alternators – Restored to meet original equipment specifications, with all wear parts replaced and standardized testing applied.

- Used Alternators – Extracted from vehicles with minimal refurbishment. Low-cost, but highly variable in performance.

Choosing to buy rebuilt alternator equipment is often a balance between budget, availability, and technical requirements.

Benefits and Limitations of Rebuilt Alternators

Benefits

- Lower acquisition cost compared to new or remanufactured units

- Availability across a wide range of vehicle makes and models

- Resource efficiency through reuse of housings and non-critical parts

Limitations

- Quality and durability may vary between suppliers

- Shorter warranty coverage compared to remanufactured units

- Potential inconsistency if testing processes are not standardized

Evaluating the Quality of a Rebuilt Alternator

A structured assessment is essential before purchase. Consider:

- Component Replacement – Brushes, rectifier, voltage regulator, bearings, and slip rings should be renewed when necessary.

- Testing Protocols – Load performance, voltage regulation, insulation resistance, and thermal endurance must be verified.

- Specification Matching – Ensure compatibility with OEM part numbers, amperage ratings, mounting design, and connector configuration.

- Documentation & Warranty – Reputable suppliers provide traceable testing records and defined service coverage.

Cost Considerations

Pricing varies according to brand, vehicle application, and electrical capacity. When deciding to buy rebuilt alternator products, it is important to factor in:

- Core return requirements and related charges

- Service labor for removal and installation

- Expected operating life compared with new or remanufactured alternatives

A total cost of ownership perspective helps in long-term procurement planning.

Procurement and Sourcing Guidelines

Organizations sourcing rebuilt alternators should:

- Confirm technical specifications using OEM references.

- Assess supplier capabilities, including testing facilities and quality assurance processes.

- Review warranty terms and after-sales support.

- Consider logistics such as lead times, packaging, and international compliance requirements.

This systematic approach minimizes operational risk and ensures consistent supply.

Installation and Operational Recommendations

- Verify alignment and belt tension during installation.

- Inspect electrical connections and grounding for secure fit.

- Avoid overloading with auxiliary electrical equipment.

- Schedule periodic inspections to extend service life.

Proper installation and maintenance practices directly influence reliability.

Frequently Asked Questions

How long does a rebuilt alternator typically last?

Service life depends on component quality and operating conditions, but properly rebuilt units can perform reliably for several years.

What distinguishes rebuilt from remanufactured alternators?

Rebuilt units involve selective replacement of defective parts, while remanufactured units are restored comprehensively to OEM specifications.

Are rebuilt alternators suitable for demanding fleet operations?

Yes, provided they meet testing standards and specification requirements. Supplier verification is key.

What should be checked before procurement?

OEM references, load testing certification, and warranty terms should all be reviewed prior to purchase.

Conclusion

Choosing to buy rebuilt alternator units can be a practical decision for organizations seeking a balance between cost efficiency and technical performance. By focusing on supplier quality, component standards, and compatibility with vehicle systems, businesses can secure reliable electrical performance while controlling procurement budgets.