Car Starter Replacement: What You Need to Know for Reliable Starting

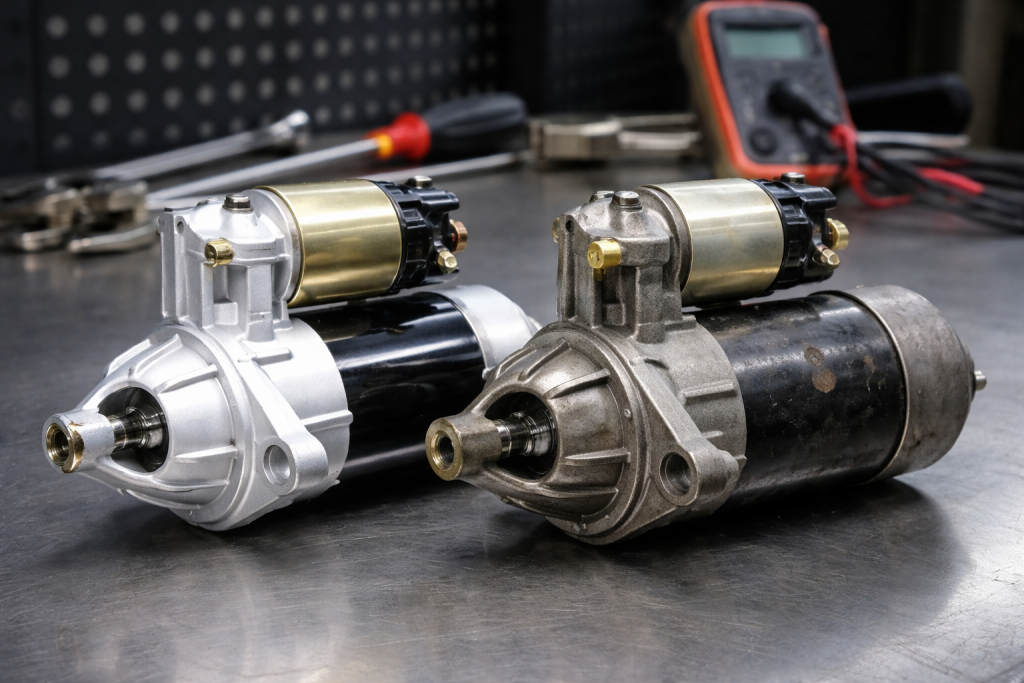

Car starter replacement becomes necessary when the starter motor can’t reliably crank the engine. A weak starter can create intermittent no-start situations that look like a battery problem—until you’re stranded. This guide explains how to recognize starter failure, confirm the cause, choose the right replacement, and avoid common installation mistakes—without guessing at costs. Starter Basics: What the Starter Motor Actually Does The starter motor turns the engine over fast enough for combustion to begin. When you turn the key (or press Start), the system typically involves: Battery power supplying current Starter relay/solenoid engaging the drive gear Starter motor cranking the engine Ignition/fuel systems taking over once the engine fires A problem anywhere in this chain can mimic starter failure, so accurate diagnosis matters before you commit to a car starter replacement. Signs You Need a Car Starter Replacement Starter issues are usually repeatable patterns, not random bad luck. Watch for: No crank (nothing happens) when you turn the key Slow crank even with a charged battery Single click or rapid clicking with no engine turnover Intermittent starting (starts fine, then won’t) Grinding sound during start attempts (engagement problem) A hot electrical smell after repeated start attempts (overheating/wiring load) If these symptoms happen more than once, treat it as a reliability problem—not a “wait and see” situation. Starter vs Battery vs Alternator: Quick Troubleshooting Before Replacement Many starting problems that look like a failing starter are actually caused by charging or battery issues. If you’re unsure which component is responsible, understanding the difference between starter and alternato can help you avoid replacing parts unnecessarily and focus on the real failure point. What it looks like vs what it often is Symptom during start Common cause What to check first Rapid clicking, no crank Weak battery / poor terminals Battery charge, terminal corrosion, ground strap Slow crank, lights dim Battery weak / high resistance Battery test, cable condition, chassis ground No sound at all Relay/ignition switch/neutral safety Starter relay, fuses, park/neutral switch One solid click, no crank Starter solenoid/motor Voltage at starter, solenoid signal wire Starts after tapping starter Starter internal wear Worn brushes/commutator inside starter If the battery tests good, cables are clean/tight, and the starter receives proper power and signal but won’t crank, car starter replacement becomes the most reliable fix. What Affects Car Starter Replacement Decisions Even if you don’t publish pricing, you should still answer the “cost intent” by explaining what drives the complexity and outcome: Starter accessibility Some starters are front-and-center; others are buried under intake components or near exhaust parts. Access affects labor time, risk of broken fasteners, and repeatability. Engine layout and heat exposure High heat can accelerate wear in wiring, solenoid contacts, and internal components—making reliability more sensitive to part quality and installation. Electrical condition of the vehicle A weak battery, corroded grounds, or voltage drop can damage a new starter over time. Fixing the root electrical issue protects the replacement. New vs rebuilt starter choice Quality depends on the manufacturer/remanufacturer standards and testing process more than the label alone. This section helps you rank against “cost pages” without publishing specific amounts—because you’re still satisfying the underlying intent. Choosing the Right Car Starter Replacement: New vs Rebuilt The “best” starter is the one that matches your vehicle and survives your usage pattern (cold starts, short trips, frequent stops, high-heat conditions). New starter replacement Choose new when you want: Maximum expected service life (model-dependent) Consistent manufacturing and warranty handling Lower risk in high-demand use (delivery fleets, frequent starts) Rebuilt (remanufactured) starter replacement Choose rebuilt when you prioritize: Practical value and reduced waste Availability for older models Strong performance if reman standards are proven What makes a rebuilt starter reliable? Look for evidence of: Replacement of wear components (brushes, bushings/bearings, solenoid contacts) Electrical load testing and engagement testing Clear warranty terms and traceable sourcing A rebuilt starter can be a strong option when it’s properly remanufactured and tested—not just cleaned and resold. Is Car Starter Replacement DIY-Friendly? Car starter replacement can be a reasonable DIY job on some vehicles—but difficult or risky on others. Use this decision table: DIY factor What “DIY-friendly” looks like Red flags (pro recommended) Access Starter visible, minimal components removed Buried under intake/exhaust, tight clearance Tools Basic sockets, extensions, jack stands Special tools, seized bolts, limited workspace Safety Clear battery isolation, stable support points Difficult lift points, limited support, near hot exhaust Electrical confidence Comfortable with terminals & routing Unsure about wiring, corrosion repair needed If you’re unsure, a professional approach reduces risk of: Cross-threaded bolts or misalignment Damaged wiring/terminals Incorrect torque leading to repeat failures Persistent no-start caused by misdiagnosis How Professional Car Starter Replacement Works (Step-by-Step) Professional starter replacement is usually structured to prevent electrical damage and repeat failures: Step 1: Confirm diagnosis before parts Battery and charging system check Voltage drop inspection on cables/grounds Starter signal verification (relay/solenoid command) Step 2: Isolate power correctly Battery disconnect (and memory-saving procedure if needed) Protect terminals and nearby wiring from shorting Step 3: Remove the old starter safely Access removal (shields, ducts, brackets as required) Disconnect wiring carefully (avoid twisting terminals) Remove mounting bolts without damaging threads Step 4: Install the replacement starter correctly Ensure mounting faces are clean and aligned Verify wiring routing isn’t pinched or heat-soaked Tighten fasteners correctly to prevent vibration issues Step 5: Post-install checks Start test (listen for clean engagement, no grinding) Inspect for heat contact, loose cables, abnormal draw Re-check grounds if intermittent cranking remains This is where your content can beat forum threads: you’re giving a repeatable, professional-safe workflow. Common Mistakes That Cause Repeat Starter Problems Even a good starter replacement can fail early if these issues aren’t addressed: Skipping cable/ground inspection Corrosion increases resistance, causing slow crank and overheating. Replacing starter without confirming battery health A weak battery can mimic starter failure and stress the new unit. Loose power cable or solenoid terminal Heat buildup and intermittent cranking often follow. Grinding ignored after replacement Grinding can indicate alignment/engagement issues that will damage the flywheel.