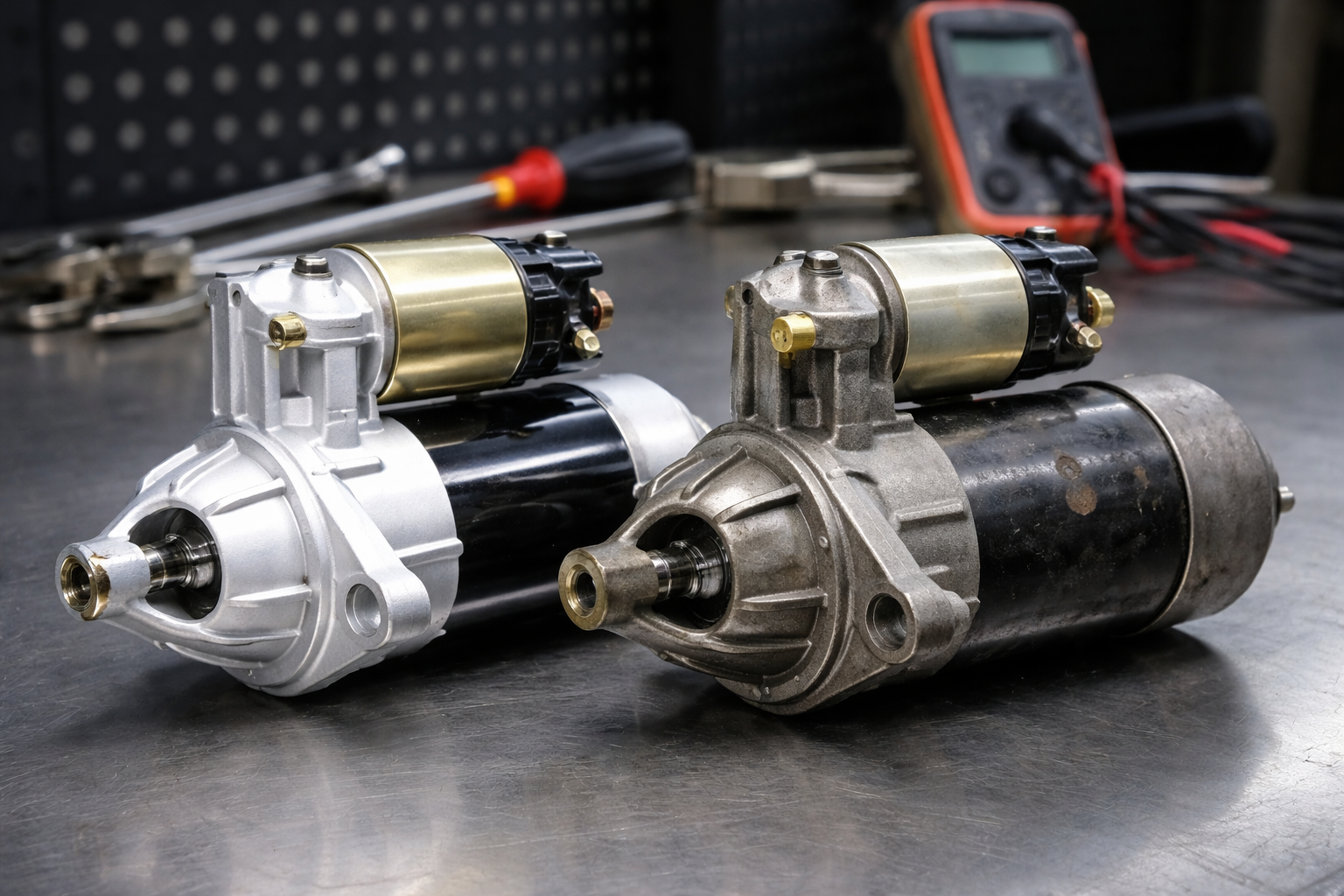

Choosing between a new vs remanufactured starter sounds simple—until you’ve had a “no-start” morning, replaced the part, and the problem returns. The truth is: both options can be reliable, and both can disappoint, depending on how the unit was built, how the vehicle is used, and whether the underlying electrical conditions are healthy.

This guide breaks down the real differences, why experiences vary so much online, and how to make a confident decision without guessing.

What the difference is between a new and a remanufactured starter

Before comparing new vs remanufactured starter, it helps to define terms the same way.

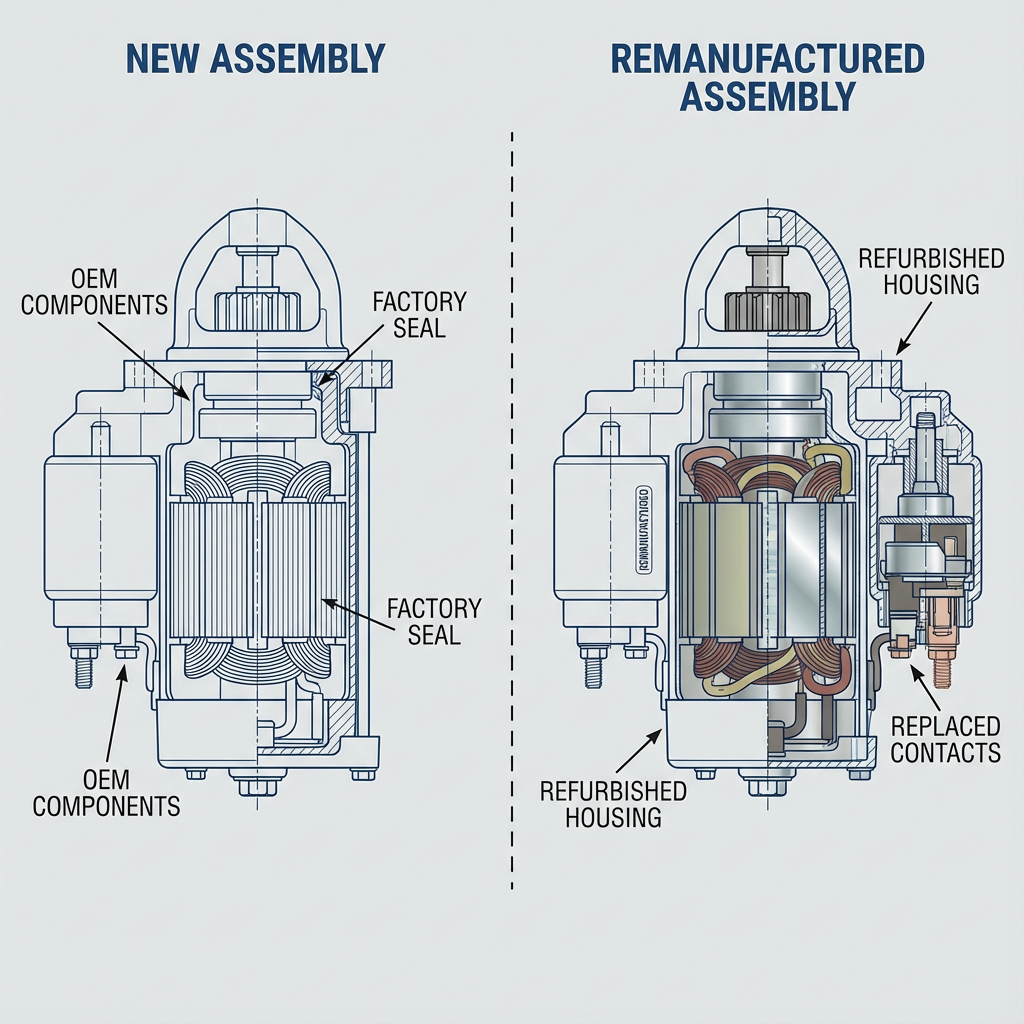

New starter

hEaQ11m&U7f#Y2QqKZ.

Remanufactured starter

A remanufactured starter is rebuilt from a used “core” in a factory-style process—typically disassembled, inspected, cleaned/machined as needed, then reassembled with replaced wear components and tested for function. The key detail is that remanufacturing standards vary by source, which is why results vary.

Rebuilt vs remanufactured

Naming varies by supplier, but a Rebuilt Starter and a remanufactured starter commonly refer to a core-based unit restored with replaced wear parts and functional testing, so evaluate the rebuild process and test standards rather than the label.

Why experiences with remanufactured starters vary so widely

If you search new vs remanufactured starter, you’ll see two extreme opinions:

- “Reman is just as good as new.”

- “Reman fails again and again.”

Both can be true—because the outcome depends on a few variables:

1

Rebuilt vs remanufactured

Naming varies by supplier, but a Rebuilt Starter and a remanufactured starter commonly refer to a core-based unit restored with replaced wear parts and functional testing, so evaluate the rebuild process and test standards rather than the label.

New vs remanufactured starter performance considerations

Instead of focusing on labels, focus on what affects day-to-day reliability.

Reliability consistency

- New starter tends to be more consistent “out of the box.”

- Remanufactured starter can be excellent when standards are strict, but consistency depends on process and core screening.

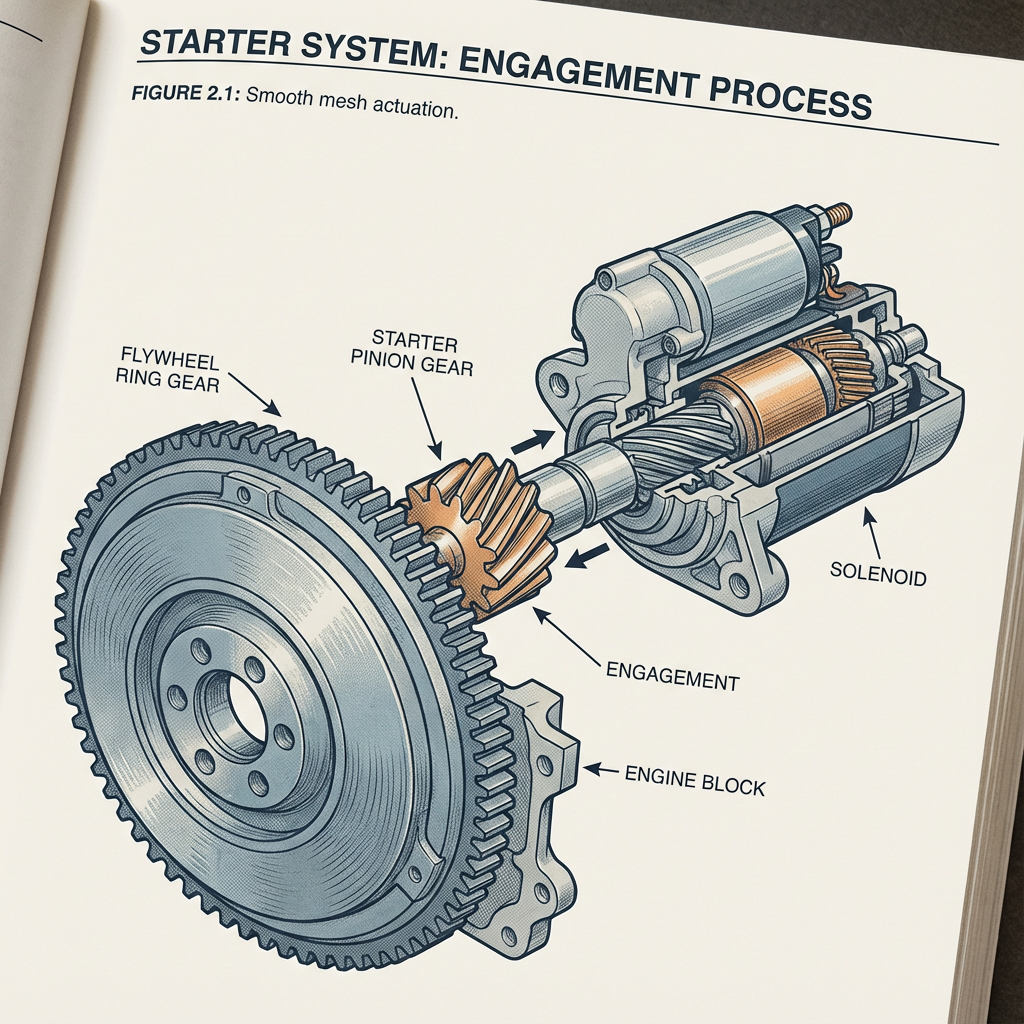

Engagement, noise, and repeatability

Grinding, harsh engagement, or repeated clicking often points to:

- installation alignment issues

- damaged ring gear/flywheel teeth

- solenoid performance issues

- wiring/voltage drop problems

Downtime tolerance

If your starter is difficult to access, doing the job twice is the real risk. Access difficulty often shifts the new vs remanufactured starter decision toward new simply to reduce repeat labor and downtime.

Which option makes sense for different use cases

This is where the decision becomes practical instead of emotional.

When a new starter is the better choice

Choose new when you want maximum predictability in situations like:

- daily drivers with frequent short trips and frequent starts

- extreme temperature conditions (cold starts or heat soak)

- commercial or fleet usage

- hard-to-access starter locations where repeat labor is costly

- long-term ownership plans where consistency matters

When a remanufactured starter can be a practical option

A remanufactured starter can make sense when:

- the vehicle is older and reliability needs are reasonable

- the starter is easy to access if replacement is ever needed again

- the reman source can clearly explain replacement and testing steps

- core return is straightforward and the original core is acceptable

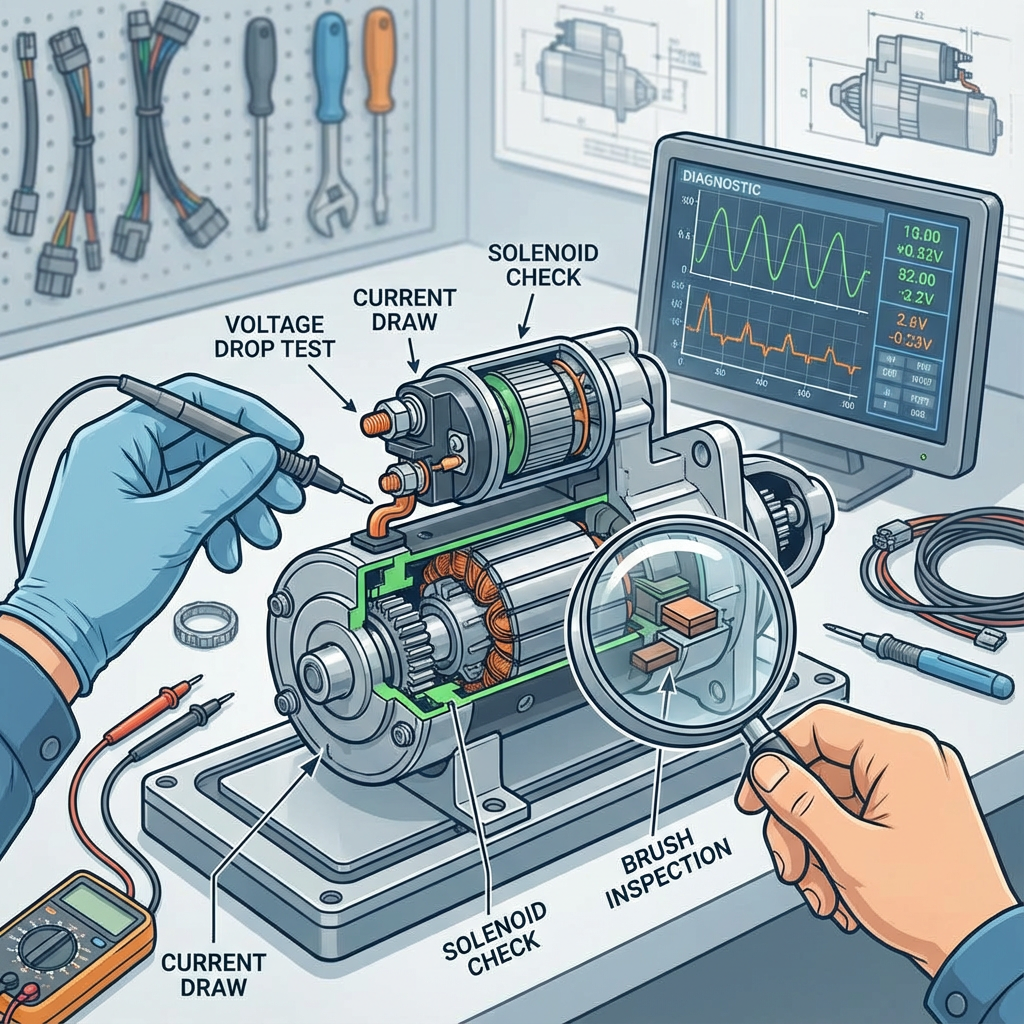

Common failure causes after starter replacement

Even a good starter can fail early if the system issues remain.

- Battery and cable issues that increase resistance and heat

- Poor grounding and voltage drop causing slow crank and overheating

- Heat shielding and cable routing problems that raise operating temperature

- Installation alignment issues leading to abnormal engagement and wear

This is why replacing the starter alone isn’t always enough to restore reliable starting.

How to evaluate remanufactured starter quality before buying

If you’re leaning toward remanufactured, this is the part that protects you from “bad batch” outcomes.

What to verify

- Which wear components are replaced by default (not only “as needed”)

- What functional tests are performed before release

- How cores are graded and screened (reject standards matter)

- Core return requirements and acceptance rules

- Warranty terms (helpful, but not a substitute for process quality)

Red flags to avoid

- “Inspected” with no mention of testing

- No clarity on wear-item replacement policy

- Inconsistent packaging or missing protective caps

- No explanation of core selection and rejection

New vs remanufactured starter decision checklist

Use this checklist to decide quickly:

- Starter access is difficult → lean new

- Frequent starts / uptime matters → lean new

- Access is easy and source is transparent → reman can work

- Electrical system condition is unknown → test battery/cables/grounds first

- Repeat failures happened before → fix voltage drop + lean new

Final thoughts for reliable starting

A new vs remanufactured starter decision is less about “which is better” and more about matching the option to your vehicle use, access difficulty, and tolerance for repeat downtime.

If reliability is mission-critical or access is painful, new is often the safer match. If access is easy and remanufacturing standards are clear and tested, a remanufactured starter can be a practical, reliable option.